Prefab shelters are among the most functional modular building systems as they offer extreme simplicity in design providing basic shelter at a very cost-effective rate. Read More…

As a modular building manufacturer, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

We offer a wide variety of affordable modular buildings for your convenience. Our engineers are determined to bring you a product with a great value and exceptional customer service. We have been around since 1954 providing portable buildings that are made out of steel.

Our booths and partitions are available in solid surface, stainless steel, solid plastic, solid phenolic, high pressure laminate, and metal powder coated. Our washroom accessories also include combo towel waste units, paper towel dispensers, waste receptacles, soap dispensers, mirrors, warm air hand dryers, toilet tissue dispensers, toilet seat cover dispensers, grab bars, bathroom accessories,...

Morgan Buildings can meet just about any modular building need. For over 60 years and 3 generations Morgan has been a pioneer and leader in modular design and construction. As a fully integrated family-operated company we design, build, transport and install modular buildings around the country and the world. From guard houses to 2-story housing complexes and everything in between we have the...

Donobrog has been a leading supplier of high-quality prefabricated modular buildings and modular offices since 1985. We offer single offices, 2-story multiunit enclosures and noise enclosures in a variety of sizes, styles and configurations. Call today for more information!

At Wilmot Modular Structures, Inc., we take pride in providing innovative modular building solutions that meet the diverse needs of our clients across a wide range of industries. We design, build, and deliver high-quality modular facilities that offer the flexibility, speed, and cost efficiency that today’s projects demand.

More Prefab Shelter Manufacturers

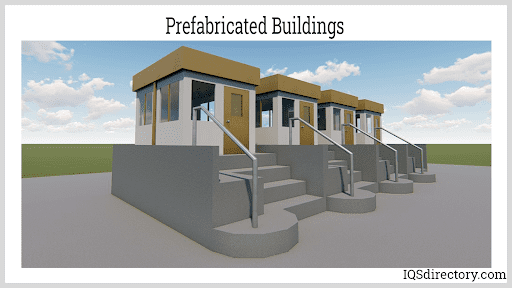

Prefab shelters, also known as modular shelters or prefabricated buildings, have revolutionized how industries, municipalities, and organizations approach rapid deployment of secure, durable structures. These shelters are typically composed of a robust frame made from steel or aluminum, topped with a durable roof, and can include walls made of polyvinyl chloride (PVC), glass, or other weather-resistant materials. Prefabricated shelter solutions are engineered to withstand harsh environmental conditions such as extreme temperatures, high winds, heavy rain, and humidity, making them ideal for both temporary and permanent installations.

What Are the Key Features of Prefab Shelters?

Prefab shelters are characterized by their quick installation, versatility, and low maintenance. They can be installed up to 80% faster than traditional on-site construction, resulting in significant savings on both materials and labor. This rapid deployment capability makes them an attractive choice for a wide range of use cases, especially where time, cost, and adaptability are critical decision factors.

- Durable Construction: Engineered frames using galvanized steel, aluminum, or precast concrete ensure longevity and resilience against environmental stressors.

- Weather Resistance: Wall and roof panels fabricated from polyvinyl, glass, or fiberglass-reinforced plastic (FRP) provide excellent protection from wind, rain, and UV exposure.

- Customization: Modular design allows for easy integration of custom features such as windows, doors, shelving, climate control, plumbing, and electrical systems.

- Factory-Built Quality: Shelter components are manufactured in controlled environments, ensuring consistent quality control and precision engineering.

- Relocatability: Many prefab shelters are fully relocatable, offering flexibility for changing project needs or temporary deployments.

- Compliance: Designs can be tailored to meet local, state, or federal building codes and security standards, including ADA compliance and ballistic protection.

Industries and Sectors Utilizing Prefab Shelters

Prefab shelters are deployed across diverse industries, meeting the needs of both commercial and government clients that require secure, reliable enclosures. Typical industries and applications include:

- Construction: Used for security enclosures, jobsite offices, tool storage, and crew shelters.

- Refrigeration & Cold Storage: Modular cold rooms and walk-in freezers for food service, pharmaceuticals, or chemical storage.

- Electronics: Secure enclosures for sensitive electronics, server rooms, and telecom equipment protection.

- Storage Solutions: Rapid-deploy storage sheds, equipment housing, and inventory management spaces.

- Automotive & Transportation: Bus stop shelters, ticket booths, toll collection booths, and vehicle inspection stations.

- Defense & Military: Guard houses, command posts, mobile shelters, and blast-resistant enclosures.

- Telecommunications: Modular shelters for cell towers, data centers, and satellite communication infrastructure.

- Medical & Healthcare: Temporary clinics, testing centers, triage shelters, and mobile medical units.

- Public Safety: Police kiosks, fire command posts, and emergency response shelters.

In addition to these sectors, prefab shelters are increasingly used for disaster relief, emergency housing, remote workforce accommodation, and as storm shelters or tornado-safe rooms. Their flexibility makes them ideal for both planned and unforeseen needs.

Common Applications for Prefab Shelters

Wondering how prefab shelters can be applied to meet your organization’s unique requirements? Here are some of the most popular and high-value use cases:

- Security Enclosures: Protect valuable equipment, personnel, or assets with reinforced and secure modular shelters.

- Machine Enclosures: Provide safe, climate-controlled environments for sensitive machinery and industrial equipment.

- Storage Sheds: Organize and secure inventory, tools, or hazardous materials in weatherproof sheds.

- Pump Houses: Protect water pumps, generators, and HVAC systems from theft, vandalism, and the elements.

- Ticket Booths: Deploy at events, parking lots, or transit stations for efficient customer service.

- Storm Shelters: Ensure occupant safety during extreme weather events with code-compliant, impact-resistant structures.

- Bus Stop Shelters: Provide commuters with comfort and protection from the elements while they wait for transportation.

- Guard Houses: Secure access control points at industrial, commercial, or military facilities.

- Information Booths: Offer guidance and assistance in public spaces, campuses, or event venues.

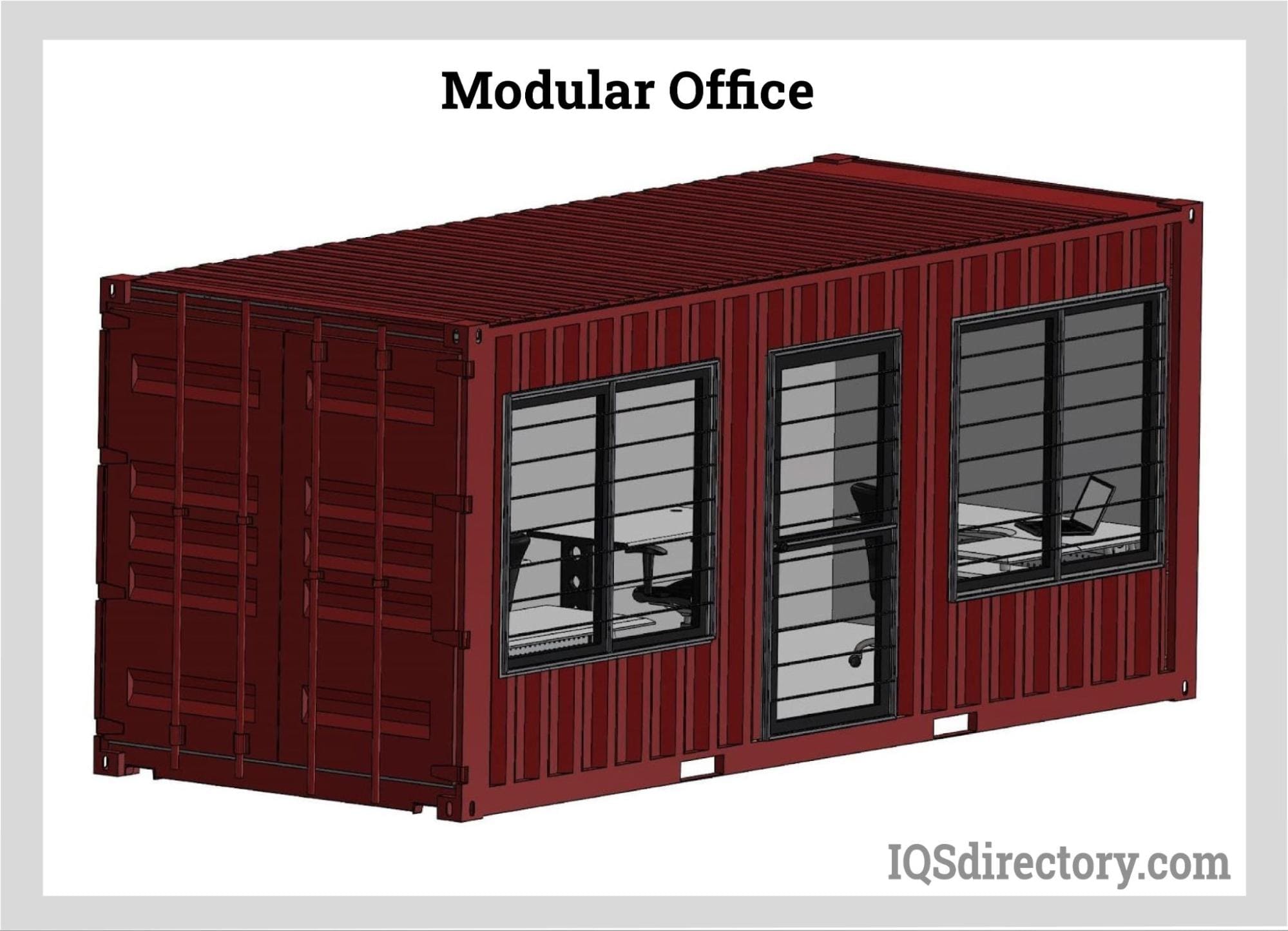

- Temporary Offices & Classrooms: Set up modular offices or educational spaces quickly during renovations or surges in demand.

- Disaster Relief Shelters: Deliver rapid, scalable shelter for displaced populations during emergencies.

Looking for a custom prefab shelter solution? Contact our team to discuss your application and requirements.

Design, Engineering, and Customization Options

Prefab shelters can be designed and engineered to meet virtually any specification or project requirement. Whether you need a simple weather-resistant enclosure or a complex, multi-room modular building with advanced MEP (mechanical, electrical, plumbing) integration, prefab shelter manufacturers can tailor solutions to your needs.

Key Design Elements

- Frame Materials: Choose from lightweight aluminum for portability, precast concrete for enhanced security, or bullet-resistant steel for high-risk applications.

- Panel Options: Select from insulated panels, glass, fiberglass-reinforced plastic (FRP), or high-impact polycarbonate walls depending on required energy efficiency and durability.

- Interior Features: Add windows, shelving, counters, HVAC systems, lighting, IT/data cabling, and more.

- Accessibility: ADA-compliant ramps, doors, and fixtures to ensure usability for all.

- Security Upgrades: Incorporate bulletproof glass, reinforced doors, surveillance systems, and electronic access control.

- Finishes: Customize interior and exterior finishes to match branding, camouflage, or local architectural styles.

Custom additions to the design of a prefabricated building may increase upfront costs, but the investment often yields long-term benefits in durability, security, and operational efficiency. Discuss your project goals with a reputable prefab shelter manufacturer to receive tailored recommendations and pricing.

Prefab Shelter Construction Process

How are prefab shelters built and installed? The process is designed for speed, quality, and minimal site disruption:

- Design & Engineering: Your requirements are translated into detailed architectural and structural plans, including any necessary code compliance or specialty certifications.

- Factory Fabrication: All major components—frames, panels, trusses, windows, doors, and interior systems—are precision-built in a controlled factory environment, ensuring consistent quality and minimizing weather delays.

- Delivery: Completed shelters or modular components are shipped directly to the prepared building site.

- On-Site Installation: Skilled crews assemble, anchor, and finish the shelter, often in a matter of hours or days, compared to weeks or months for traditional construction.

- Commissioning & Handover: Final inspections, utility connections, and handover to the client for immediate use.

Advantages of Prefab Shelters vs. Conventional Construction

Why choose prefab shelters over traditional building methods? Explore the key advantages that drive organizations to select modular, factory-built structures:

- Speed: Factory-controlled production allows for rapid project turnaround, ideal for urgent deployments or tight schedules.

- Cost Efficiency: Reduced labor and material waste, plus predictable project budgets.

- Quality Control: Manufacturing in a regulated environment ensures precision, consistency, and fewer construction defects.

- Flexibility: Easily expand, reconfigure, or relocate modular shelters as needs change.

- Minimal Site Disruption: Shorter on-site construction times mean less disturbance to ongoing operations or sensitive environments.

- Sustainability: Prefab shelters can incorporate energy-efficient materials, recycled components, and meet green building standards.

- Low Maintenance: Durable materials and finishes reduce lifecycle maintenance costs and downtime.

Decision Factors When Purchasing Prefab Shelters

Considering a prefab shelter for your next project? Here are the top factors buyers evaluate when researching and selecting modular shelter solutions:

- Intended Use: Define your primary application and required features—security, climate control, size, and occupancy.

- Site Conditions: Assess space constraints, ground preparation, access, and utility requirements.

- Budget: Factor in both upfront investment and total cost of ownership, including installation, maintenance, and potential relocation.

- Compliance: Ensure the shelter meets local codes, zoning, and any specialized certifications (e.g., fire resistance, ballistic protection).

- Customization: Determine which features are essential versus optional for your specific use case.

- Lead Time: Confirm manufacturing and delivery timelines to align with your project schedule.

- Vendor Reputation: Choose a supplier with a proven track record of quality, service, and post-installation support.

Have questions about specifying or pricing a prefab shelter? Request a detailed quote or speak with our experts for a custom consultation.

Frequently Asked Questions About Prefab Shelters

What is the typical lifespan of a prefab shelter?

With proper maintenance, high-quality prefab shelters can last 20-50 years or more, depending on materials, location, and exposure to environmental factors.

Can prefab shelters be relocated?

Yes. Many modular shelters are designed for easy disassembly and relocation without structural compromise, making them ideal for temporary projects or changing site needs.

Are prefab shelters energy efficient?

Modern prefab shelters can be built with high-performance insulation, reflective roofing, and energy-saving HVAC systems, meeting or exceeding energy efficiency standards for commercial buildings.

How long does installation take?

While timelines vary by size and complexity, most prefab shelters can be installed and operational in days rather than weeks or months.

Can I customize the appearance and layout?

Absolutely. Manufacturers offer a wide range of customization options, from exterior finishes and colors to interior layouts, window placement, and branding.

Next Steps: How to Choose the Right Prefab Shelter Manufacturer

Ready to take the next step toward a modular, prefabricated shelter solution? Here’s how to get started:

- Research Suppliers: Look for experienced manufacturers with robust portfolios, industry certifications, and positive client testimonials.

- Request Case Studies: Review real-world examples of successful prefab shelter installations in your industry.

- Ask About Warranties: Ensure the manufacturer offers comprehensive product warranties, installation support, and ongoing service.

- Discuss Logistics: Confirm lead times, shipping, site preparation, and installation services to avoid surprises.

- Evaluate Total Value: Consider not just price, but also durability, flexibility, and long-term operational savings.

Start your prefab shelter project today—contact a prefab shelter expert for a personalized consultation or to schedule a design review.

Prefab shelters represent a modern, efficient, and cost-effective alternative to traditional construction, adaptable for a wide range of industries and applications. By leveraging modular construction technology, organizations can deploy secure, high-quality structures—faster, and often at a lower total cost of ownership. Whether you need a temporary solution or a permanent building, prefab shelters deliver unmatched flexibility, safety, and value for any project.

55 Gallon Drums

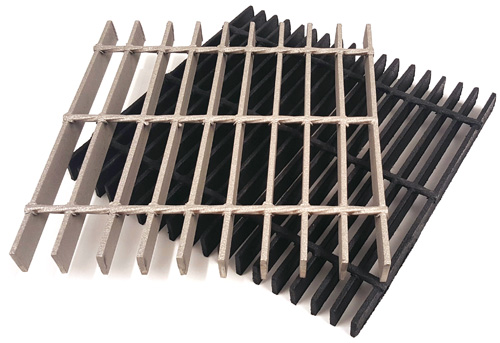

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services